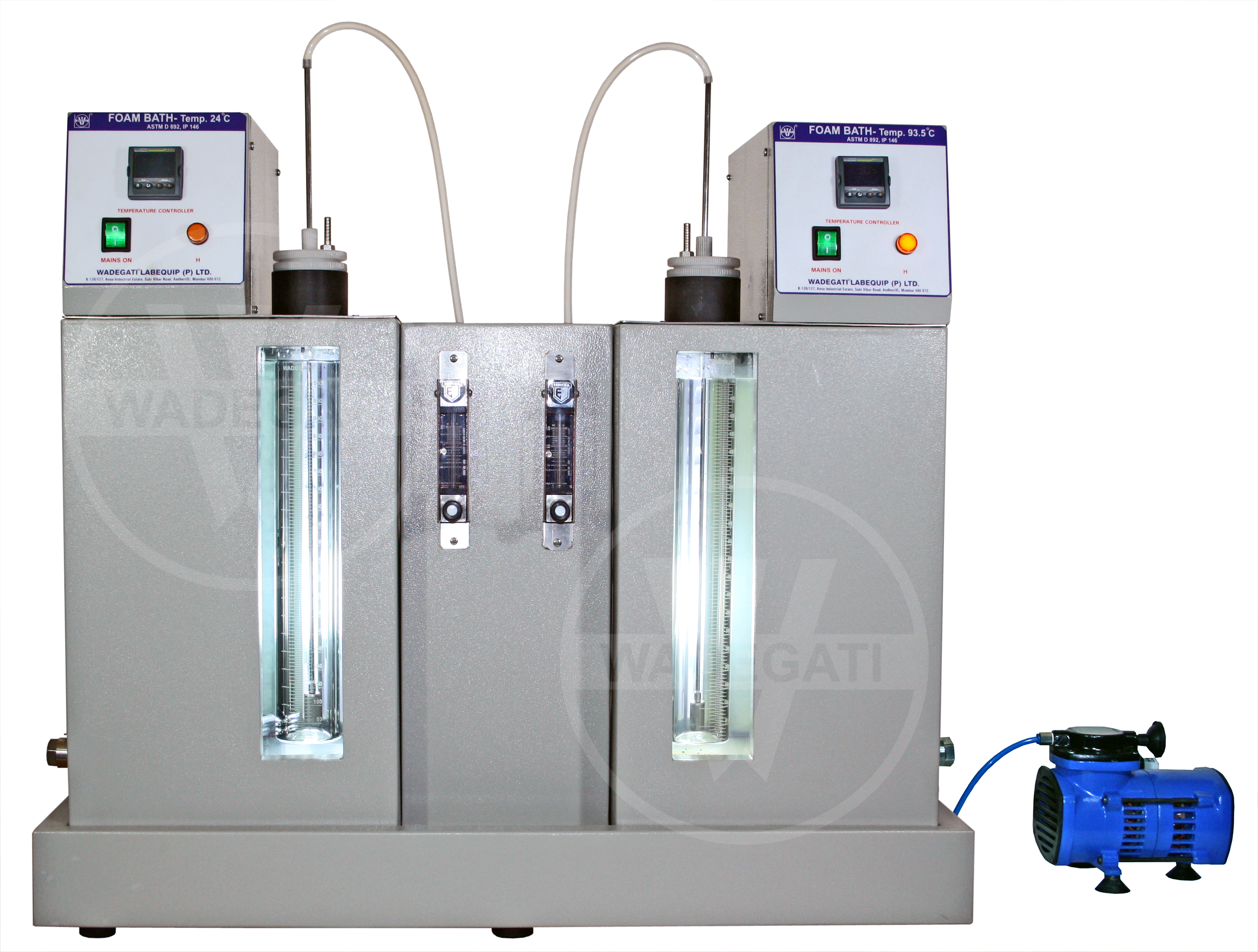

FOAM BATH

As per ASTM D-892, ASTM D-6082, IP 146, DIN 51566.

- Foaming of lubricating oils in applications involving turbulence, high speed gearing or high volume pumping can cause inadequate lubrication, cavitation, overflow and premature oxidation. The

sample is blown with a controlled volume of air at different specified temperatures. The resultant foam is measured at the end of each aeration period and at different intervals afterwards. - Rectangular double foam test model with double walled construction with toughened glass observation window and illumination at rear.

- Consist of two test bath large enough to permit immersion of 1 No, 1000ml graduated cylinder in each bath with stirrer and heater. Cooling coil installed in 24ºC bath.

- Digital temperature controller with PT-100 sensor.

- Air flow meter with needle valve to maintain an airflow rate of 94 ± 5ml/min through the gas diffuser stone cylindrical metal diffuser with stainless steel pipe & tubing.

- Electric air compressor diaphragm type and moisture absorption system.

- Temperature accuracy : 24°C, ± 0.5°C & 93.5°C, ± 0.5°C, suitable for I, II & III sequence.

- Power supply : 220 V, 1 Phase, 50 Hz.

FOAM BATH

As per ASTM D-892, ASTM D-6082, IP 146, DIN 51566.

- Foaming of lubricating oils in applications involving turbulence, high speed gearing or high volume pumping can cause inadequate lubrication, cavitation, overflow and premature oxidation. The sample is blown with a controlled volume of air at different specified temperatures. The resultant foam is measured at the end of each aeration period and at different intervals afterwards.

- Rectangular double foam test model with double walled construction with toughened glass observation window and illumination at rear.

- This method consist of two test bath large enough to permit immersion of 2 nos, 1000ml graduated cylinder in each bath with stirrer, heater and cooling coil installed in 24ºC bath.

- Digital temperature controller with PT-100 sensor.

- Digital thermal mass flow meter with computer interfacing incorporated to maintain an airflow rate of 94 ± 5ml/min through the gas diffuser stone.

- Digital Data Logger consist of 8 Channel with computer interfacing to log bath temperature @ 24ºC, 93.5ºC, Air Flow rate at 94ml/min of 24ºC bath & 93.5ºC bath

- Electric air compressor diaphragm type operated through digital timer with moisture absorption system.

- Temperature : 24°C, ± 0.5°C & 93.5°C, ± 0.5°C, suitable for I, II & III sequence.

- Power supply : 230 V, 1 Phase, 50 Hz.