STABILITY CHAMBERS (LAB MODEL)

Stability test chambers are especially built to pass FDA and ICH Q1A compliance standards and have a reputation for reliability, quality and performance. Exceed FDA / ICH guidelines for long term, Intermediate and Accelerated Stability studies.

- Construction as per cGMP regulations.

- Consisting of refrigeration, air handling, humidification, dehumidification, temperature/humidity controlling

- Microprocessor based 2 channel multifunctional PID Temperature / Humidity (RH) controller for simultaneous control of temperature and % RH OR PLC based system for chamber control and auto changeover of standby system

with touch screen display. - Printer interface & PC interface for data storage

- Standard networking via Ethernet.

- Standard temperature & RH configuration.

25°C / 60% RH

30°C / 65% RH

40°C / 75% RH - Specially designed chambers are available to carry out stability studies at low temperature and low humidity conditions such as

25°C / 40% RH,

40°C / 25% RH,

30°C / 35% RH,

40°C / 15% RH,

55°C / 20% RH and

55°C / 75% RH.

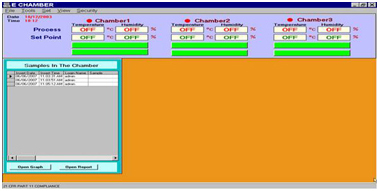

Data Acquisition system complying to US FDA 21 CFR Part 11

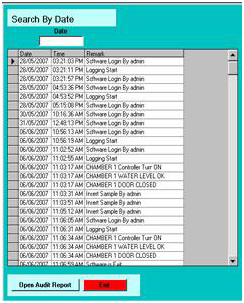

- Data records & process control systems have Electronic Signature & Electronic Record capability. The controllers have a lockout feature that permits changes through a 21CFR Part11 compliant operator station, thus providing the necessary audit trail.

- Mean Kinetic Temperature value.

- Password security for log in and door operations.

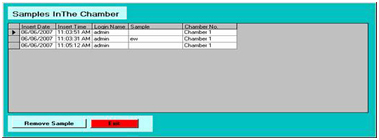

- Operators need to enter user name and password before taking any action.

- Report search option using date and sample name.

- Secure computer generated, time stamped runtime audit trail of batch stop/start, alarm acknowledgements,logins, signature details, configuration changes.

- User actions with signing and authorization.

- Access control according to authority level.

- Export conversion facility to Excel.

| Temperature Range | : 20°C to 60°C |

| Accuracy | : ± 0.2°C |

| Temperature uniformity | : ± 2°C. |

| Humidity Range | : 40% to 95% |

| Accuracy | : ± 2% RH |

| Humidity Uniformity | : ± 3% RH |

| Power supply | : 1 Phase, 230V ± 10% AC, 50 Hz. OR 3 Phase, 440V. |

- Temperature and RH Data Logger :

8 channel (4 temperatures + 4 humidity) or 16 channel (8 temperature + 8 humidity), calibrated data logger to print date, time, temperature and humidity set and process values for mapping and auto validation. Features like printer and PC interfacing. - Standby Systems : Standby refrigeration, humidity and RH sensor

- Mobile Alert :

- Different Alarm indication through Mobile SMS Alert (from single to multi user)

- Process value indication through Mobile SMS Alert(from single to multi user)

- Validation : DQ/ FAT /IQ / OQ / PQ documentation with test and calibration certificate.

- Safety features :

- Audio alarm provided to signal variation in temperature and relative humidity.

- Water level alarm & indicating device :

Safety digital temperature controller. - Dedicated safety system to shut off the Boiler heater and air heater in case of over shoot of temperature by giving Audio visual alarm.

- In built over load protector provided for hermetically sealed compressor.

| Models | Capacity | Internal chamber | External dimension | Weight (Kg) | Maximum trays |

| Litres | dimension | W x D x H (mm) | can be | ||

| W x D x H (mm) | accommodated | ||||

| WIL-195A | 90 | 450 x 450 x 450 | 710 x 970 x 1070 | 125 | 2 |

| WIL-195B | 200 | 600 x 450 x 750 | 800 x 1000 x 1370 | 175 | 3 |

| WIL-195C | 400 | 600 x 600 x 1100 | 800 x 1140 x 1720 | 250 | 4 |

| WIL-195D | 800 | 800 x 750 x 1300 | 1000 x 1300 x 1930 | 315 | 8 |

| WIL-195E | 1000 | 800 x 800 x 1520 | 1000 x 1360 x 2150 | 355 | 10 |