Key Features

-

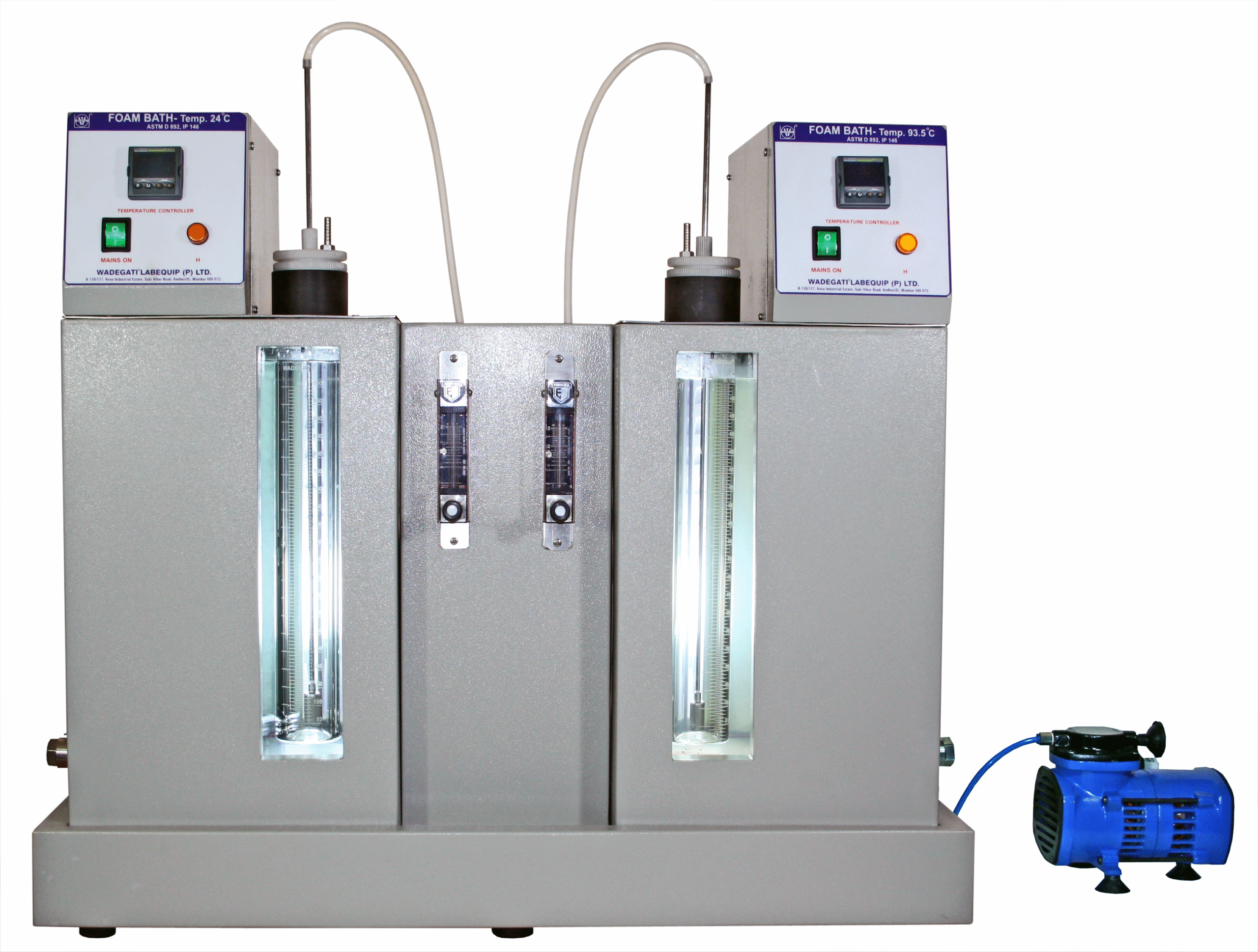

Double-Walled Test Chamber

-

Rectangular model with toughened glass observation window and rear illumination for clear visibility.

-

Two independent baths for conducting Sequence I, II, and III tests at different temperatures.

-

-

Temperature Control & Stability

-

Digital PID temperature controller with PT-100 sensor.

-

Temperature range: 24°C ± 0.5°C and 93.5°C ± 0.5°C.

-

Cooling coil in 24°C bath for precise control.

-

-

Airflow Regulation

-

Precision airflow rate maintained at 94 ± 5 mL/min through cylindrical metal diffuser with stainless steel tubing.

-

Advanced models include digital thermal mass flow meter with computer interfacing for automated monitoring.

-

-

Data Logging & Automation

-

8-channel data logger for temperature and airflow rate monitoring, integrated with computer software.

-

Digital timer-controlled diaphragm air compressor with moisture absorption system.

-

Technical Specifications

-

Bath Capacity: 2 × 1000 mL graduated cylinders

-

Observation Window: Toughened glass with illumination

-

Power Supply: 230 V AC, 50 Hz, Single Phase

Applications

-

Determination of foaming tendency in lubricating oils, hydraulic fluids, and turbine oils

-

Ideal for refineries, lubricant manufacturers, and QA/QC laboratories

Reviews

There are no reviews yet.