Key Features

-

Glass Tube Design:

-

High-quality sealed glass tubes with rounded bottom, ideal for refrigerant-lubricant testing.

-

-

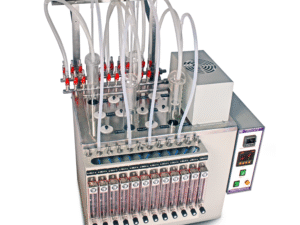

Refrigerant Charging Assembly:

-

Metal manifold for 4 samples, equipped with vacuum pump, manometer (3′ length), pressure gauge, high vacuum gauge, valves, and filling ports.

-

-

Tube Sealing Assembly:

-

Includes blow pipe gun, adjustable manifold fixture, gloves, safety shield, pressure gauge, flashback arrestor, and double-stage high-pressure regulator for safe sealing.

-

-

Tube Opening Assembly:

-

Designed for safe and convenient opening of sealed glass tubes for post-test analysis.

-

-

Flexible Tubing:

-

High-quality PVC or rubber tubing for sealing operations.

-

-

Dewar Flask for Liquid Nitrogen:

-

Made from 304 AISI stainless steel, 2 mm thick with PUF insulation for efficient cooling.

-

-

Aluminum Block for Ageing:

-

Holds 12 tubes for uniform heating during ageing tests.

-

-

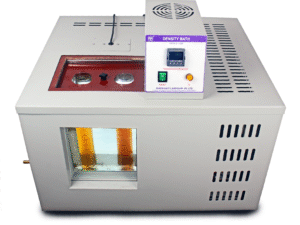

Ageing Oven:

-

Cross-flow circulatory oven with digital temperature controller, capable of operating up to 250°C.

-

-

Power Supply:

-

230 V ±10%, 1 Phase, 50 Hz

-

Technical Highlights

-

Temperature Control: Digital PID for precise ageing conditions

-

Capacity: Up to 12 tubes simultaneously

-

Vacuum System: High vacuum gauge and pump for accurate refrigerant charging

-

Safety: Includes pressure control, shielding, and safety regulators

Applications

-

Evaluation of lubricant-refrigerant compatibility

-

Chemical stability testing for metal components in refrigeration systems

-

Ideal for HVAC industry, lubricant manufacturers, and research labs

Reviews

There are no reviews yet.