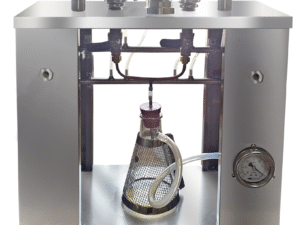

Key Features

-

Standard Compliance: Suitable for oxidation stability testing as per ASTM methods.

-

Dual-Test Capability:

-

2-place rotating pressure vessel oil bath for simultaneous sample analysis.

-

-

Precision Temperature Control:

-

Digital electronic temperature controller with fail-safe mechanical thermostat.

-

-

Heavy-Duty Drive System:

-

Robust motor rotates vessels at 100 RPM, housed beneath the oil bath.

-

-

Pressure Vessel Design:

-

Stainless steel construction, angled at 30°, with stem and valve to connect a pressure transducer.

-

-

Temperature & Pressure Range:

-

Temperature: Ambient to 200°C

-

Pressure: 0–200 psi mapping.

-

-

Large Bath Capacity:

-

70 liters with stainless steel body and cover.

-

-

Supplied Accessories:

-

Catalyst wire, glass liners with PTFE cover, ASTM 96C thermometer, ‘O’ ring.

-

-

Data Logging:

-

Automatic pressure digital data logger with PC interface and software (CD-ROM).

-

Technical Specifications

-

Capacity: 2 rotating vessels

-

Rotation Speed: 100 RPM

-

Temperature Accuracy: ±0.5°C

-

Power Supply: 230 V, 1 Phase, 50 Hz

Applications

-

Engine oil oxidation stability testing

-

Turbine oil performance analysis

-

Insulating fluid aging studies

-

Quality control and research laboratories

Reviews

There are no reviews yet.