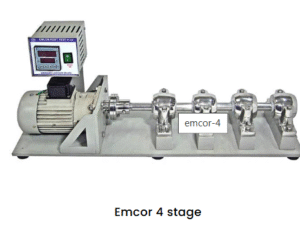

Key Features

-

Precision Ventmeter Testing: Measures grease ventability under real-world pressure and temperature conditions.

-

Wall-Mounted Design: Ventmeter fixed on wall for ease of operation and stability.

-

Sturdy Support Stand: Heavy-duty stand supports the grease gun assembly for safe handling.

-

Easy Filling & Operation: Grease gun can be dismantled for filling up to ~1 kg of grease, then easily re-assembled on the test system.

-

Industrial Simulation: Helps prevent over- or under-lubrication, ensuring optimal grease flow and system efficiency.

Technical Highlights

| Parameter | Specification |

|---|---|

| Grease Requirement | ~1 kg per test |

| Mounting | Wall-mounted Ventmeter |

| Support | Sturdy stand for grease gun |

| Test Focus | Ventability and re-pressurization of grease |

Typical Uses

-

R&D and QC testing of greases for centralized automatic lubrication systems

-

Performance evaluation of grease flow under pressure and venting cycles

-

Verification of lubricant compatibility with high-pressure industrial systems

Benefits

-

Ensures accurate and consistent lubrication in automated systems

-

Prevents costly failures due to over-lubrication or insufficient grease delivery

-

User-friendly setup with wall-mounted Ventmeter and sturdy gun support

-

Reliable testing method that simulates real-world industrial conditions

Reviews

There are no reviews yet.