Key Features:

-

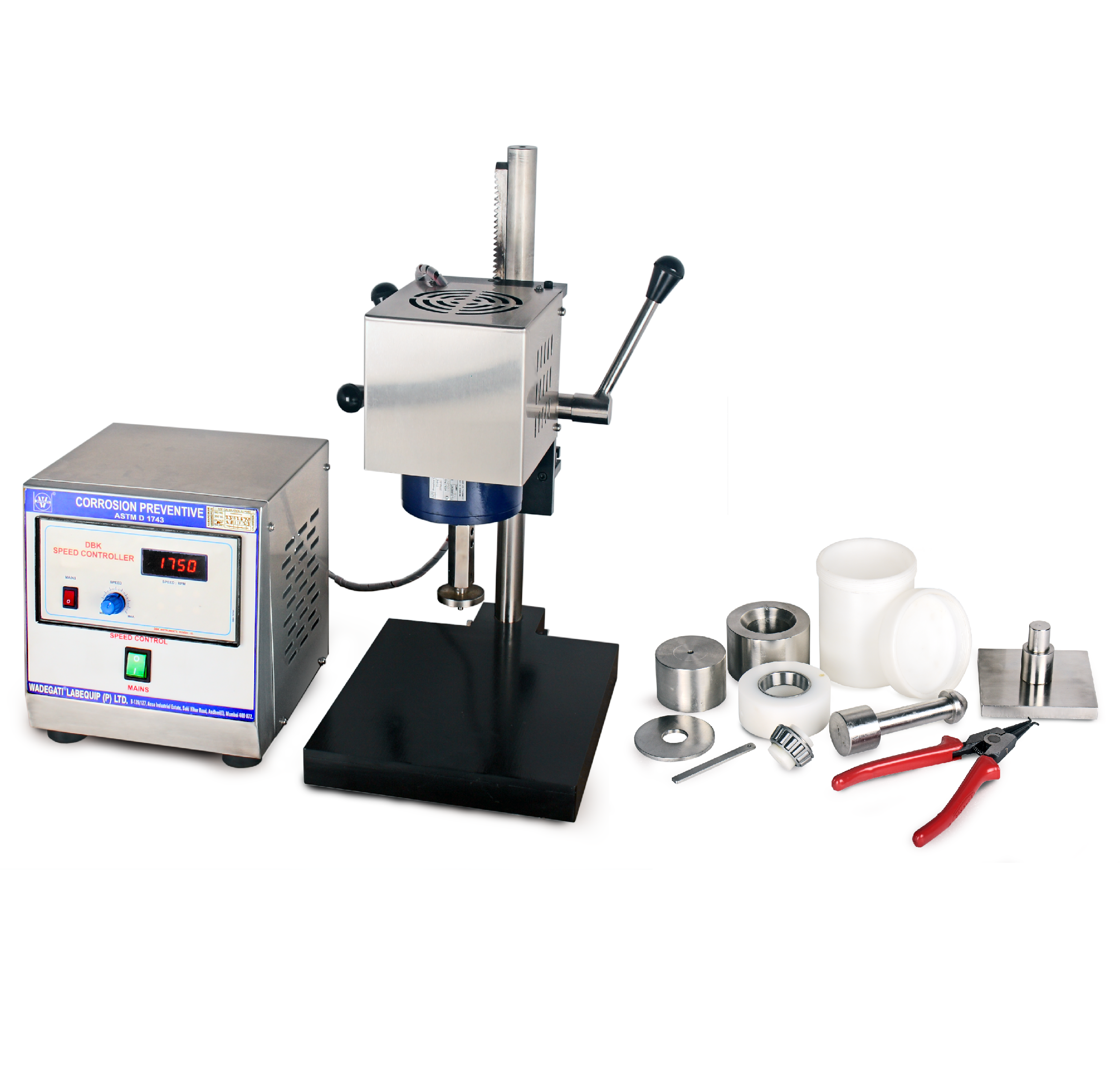

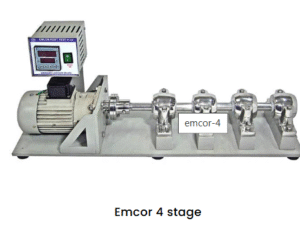

Corrosion resistance testing for grease-lubricated bearings

-

High-speed motor (1750 ± 50 rpm) with digital RPM display & regulator

-

Durable Timken bearing cone and roller assemblies

-

Complete set with bearing holder, test jar, run-in stand, and grease packer

-

Power Supply: 230 V ±10%, 1 Phase, 50 Hz

Applications:

-

Quality control testing of lubricating greases

-

Research & Development for industrial lubrication products

-

Compliance testing as per international standards

Reviews

There are no reviews yet.