Key Features

-

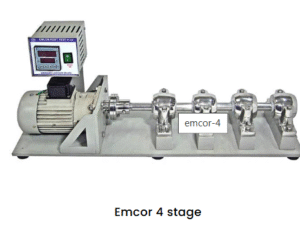

Integrated Test Assembly: Modified steel spindle & front wheel hub with thermocouple, thrust loading device, anodized aluminum grease collector.

-

Automatic Control & Display: Continuous digital readouts of motor torque, rpm, chamber temperature, spindle temperature, active cycle status, elapsed time.

-

Variable Speed Drive Motor: Base speed 1725 rpm with closed‑loop control driving hub at specified 1000 rpm test speed.

-

Constant Temperature Oven: Insulated enclosure with 1800 W heater and forced air circulation for uniform heat; maintains spindle temperature at 160°C ±1.5°C.

-

Cyclic Operation Logic: Programmable on/off (e.g. 20 h on / 4 h off) with automatic end‑point detection.

-

Safety & Reliability: Automatic shutdown at calibrated torque end point; 30 s surge filter prevents false trips.

-

Ergonomic Access: Sliding doors & swing‑out / movable platform provide fast access to spindle for loading & inspection.

-

Robust Data Integrity: Digital time cycle and cumulative on‑cycle hour recording.

-

Construction: Durable laboratory-grade materials for continuous high-temperature operation.

-

Power Supply: 230 ±10% V AC, 1 Phase, 50 Hz.

Typical Applications

-

Comparative grease life / longevity studies at elevated temperature.

-

R&D formulation screening for automotive wheel bearing greases.

-

Quality control / batch certification of high-performance lubricating greases.

-

Failure mode & performance benchmarking for thermal oxidation and mechanical shear stability.

Performance Advantages

-

Reproducible torque‑based end point for objective grease life measurement.

-

Uniform thermal environment ensures consistent spindle temperature.

-

Automated duty cycle reduces operator intervention and labor time.

-

Real‑time torque monitoring helps diagnose degradation progression.

Reviews

There are no reviews yet.