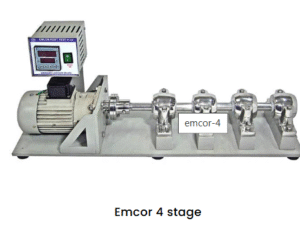

Key Features:

-

Accurate Simulation: Tests grease leakage in modified automotive spindle-hub assembly as per industry standards.

-

High-Temperature Operation: Performed in a digitally controlled oven for consistent thermal conditions.

-

Forced Air Circulation: Electrically heated oven with powerful motor-driven air circulation for uniform heat distribution.

-

Robust Test Setup: Includes wheel bearing spindle, front wheel hub, driving belt pulley, leakage collector, front and rear roller bearings.

-

Precise Measurement: Collects and measures leakage for accurate evaluation of grease performance.

-

Power Supply: 440 V, 3 Phase operation.

Applications:

Ideal for automotive manufacturers, lubricant formulators, and quality control laboratories to assess grease leakage tendencies under operational stress conditions.

Reviews

There are no reviews yet.